Promising chemical discovery offers hope for cheaper prescriptions

- Replies 0

Big breakthroughs sometimes come from unexpected places, and this latest one could change the way everyday medicines are made.

For decades, the cost of creating life-saving drugs has weighed heavily on patients, especially in the US, where pharmaceutical prices are a constant point of debate.

Behind the high price tags is often the complex science that goes into making certain compounds.

Now, researchers believe they may have found a way to simplify part of that process—and potentially make critical medications far more affordable.

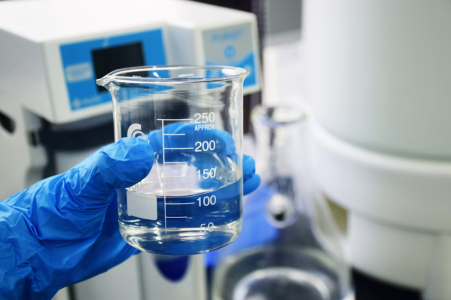

A team from the University of Maine, the USDA Forest Products Laboratory, and the University of Wisconsin has developed a new pathway to create a key chemical building block used in some of the world’s most prescribed drugs.

This molecule, known as (S)-3-hydroxy-γ-butyrolactone (HBL), plays a role in producing statins, antibiotics, and HIV inhibitors.

Traditionally, making HBL has required expensive fossil-based processes involving multiple reaction steps and costly purification methods.

By contrast, the new approach uses renewable glucose and produces the compound at high concentrations and efficiency.

“Ours is not the first process to make HBL starting from renewable sugars, but we think it is one of the simplest processes that have been discovered so far,” researchers Thomas Schwartz and Philip Kersten told Newsweek.

The method combines a biochemical process involving only two enzymes with a chemical process that uses inexpensive acids and bases.

That streamlined approach cuts down on waste, reduces the need for hazardous materials, and eliminates some of the challenges that have plagued previous experiments.

Early analysis suggests production costs could be slashed by more than 60 percent compared to petroleum-derived methods.

Also read: Costco shopper shares “secret code” for cheaper meds—members say they’re stunned

The real innovation lies in using glucose from woody biomass, including sawdust, branches, and paper byproducts, as the raw material.

Unlike fossil fuels, these resources are renewable, widely available, and sustainable. “If we use other kinds of wood sugars, like xylose that is an unneeded byproduct from making pulp and paper, we expect that we could produce new chemicals and building blocks, like green cleaning products or new renewable, recyclable plastics,” Schwartz explained.

The Department of Energy has already flagged HBL as a highly valuable precursor not only for pharmaceuticals but also for chemicals and plastics.

For patients, the ripple effect could be enormous if the process proves scalable. Many of the most expensive prescription drugs are “chiral,” meaning their molecules exist in mirrored forms that are difficult and costly to produce.

Also read: Why reviewing your Medicare plan every year could save you money and stress

By making one of the core building blocks cheaper and greener, researchers say it may open the door to affordable treatments for conditions ranging from high cholesterol to infectious diseases.

“The next steps are to work on scaling up the process, which will reveal where bottlenecks are and eventually could lead to commercial production,” Schwartz and Kersten added.

Read next: Could SeniorCare help cut your prescription costs? Some seniors in this state are finding out

Would you welcome more medicines made from renewable resources if it meant significantly lower costs, or do you think the pharmaceutical industry will still find ways to keep prices high? Share your thoughts in the comments—we’d love to hear how you see this breakthrough shaping the future of healthcare.

For decades, the cost of creating life-saving drugs has weighed heavily on patients, especially in the US, where pharmaceutical prices are a constant point of debate.

Behind the high price tags is often the complex science that goes into making certain compounds.

Now, researchers believe they may have found a way to simplify part of that process—and potentially make critical medications far more affordable.

A team from the University of Maine, the USDA Forest Products Laboratory, and the University of Wisconsin has developed a new pathway to create a key chemical building block used in some of the world’s most prescribed drugs.

This molecule, known as (S)-3-hydroxy-γ-butyrolactone (HBL), plays a role in producing statins, antibiotics, and HIV inhibitors.

Traditionally, making HBL has required expensive fossil-based processes involving multiple reaction steps and costly purification methods.

By contrast, the new approach uses renewable glucose and produces the compound at high concentrations and efficiency.

Promising chemical discovery offers hope for cheaper prescriptions. Image source: RephiLe water / Unsplash

“Ours is not the first process to make HBL starting from renewable sugars, but we think it is one of the simplest processes that have been discovered so far,” researchers Thomas Schwartz and Philip Kersten told Newsweek.

The method combines a biochemical process involving only two enzymes with a chemical process that uses inexpensive acids and bases.

That streamlined approach cuts down on waste, reduces the need for hazardous materials, and eliminates some of the challenges that have plagued previous experiments.

Early analysis suggests production costs could be slashed by more than 60 percent compared to petroleum-derived methods.

Also read: Costco shopper shares “secret code” for cheaper meds—members say they’re stunned

The real innovation lies in using glucose from woody biomass, including sawdust, branches, and paper byproducts, as the raw material.

Unlike fossil fuels, these resources are renewable, widely available, and sustainable. “If we use other kinds of wood sugars, like xylose that is an unneeded byproduct from making pulp and paper, we expect that we could produce new chemicals and building blocks, like green cleaning products or new renewable, recyclable plastics,” Schwartz explained.

The Department of Energy has already flagged HBL as a highly valuable precursor not only for pharmaceuticals but also for chemicals and plastics.

For patients, the ripple effect could be enormous if the process proves scalable. Many of the most expensive prescription drugs are “chiral,” meaning their molecules exist in mirrored forms that are difficult and costly to produce.

Also read: Why reviewing your Medicare plan every year could save you money and stress

By making one of the core building blocks cheaper and greener, researchers say it may open the door to affordable treatments for conditions ranging from high cholesterol to infectious diseases.

“The next steps are to work on scaling up the process, which will reveal where bottlenecks are and eventually could lead to commercial production,” Schwartz and Kersten added.

Read next: Could SeniorCare help cut your prescription costs? Some seniors in this state are finding out

Key Takeaways

- A new chemical process developed by US researchers could make prescription drugs far cheaper by simplifying the production of a key chiral building block.

- The breakthrough uses glucose from woody biomass instead of fossil fuels, making it both more sustainable and more affordable.

- Early tests show production costs could drop by over 60 percent, which could lower the price of statins, antibiotics, and HIV medications.

- The team is now focused on scaling up the process for commercial use. If successful, it may also create opportunities for renewable plastics and green consumer products alongside cheaper medicines.